THERMOBLOW-blow-in machines for the insulation on construction site

Experience and Know-how

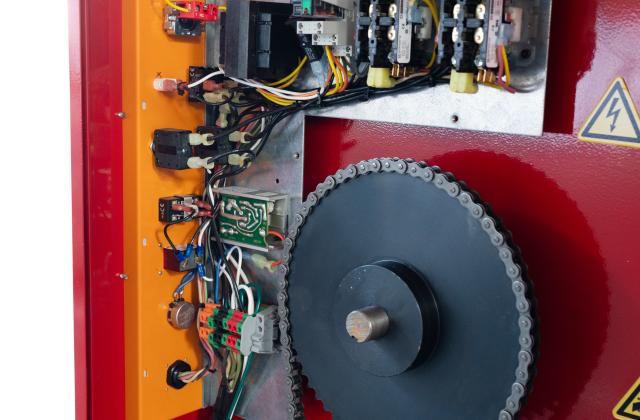

THERMOFLOC has decades of experience in the field of blow-in technology. Based on our expertise in the practical use of blown-in insulating materials, we have developed several different types of blowing machines. Specialist processing companies in particular appreciate our expertise in blow-in technology as well as the high quality and efficiency of our machines. All machine versions are characterised by short setup times, manageability and excellent performance. The mechanical relay technology ensures low-maintenance continuous operation. Accessories and spare parts are easily and quickly available.

Blow-in technology x 2: our machines

THERMOBLOW 200

The most cost-efficient and smallest 230 V machine when it comes to blow-in technology. The insulating material compressed in the bags is broken up in material containers and loosened with the help of agitator arms. The loosened insulating material moves into the rotary vane feeder where the air pressure created by 1 blower feeds it into the hoses and then into the cavities to be insulated. This machine type is suitable for processing cellulose and EPS blown-in insulating materials.

| Performance features | |

|---|---|

| 1. Power/material processing speed | 800 kg |

| 2. Drive motor | 1,0 hp / 0,75 kWh |

| 3. Connected load | 230 V/16 Amp. |

| 4. Blower | 1 x 1,6 kWH |

| 5. Blower control | Manual |

| 6. Agitator speed control | Manual |

| 7. Amount of material control | Material slider |

| 8. Opening rotary feeder | V = ca. 13,7 l |

| 9. Dimensions (L x W x H) | 56 x 71 x 160 cm |

| 10. Weight without accoessories | ca. 130 kg |

| 11. Hopper size | ca. 0,4 m³ |

| 12. Machine control | Radio remote control |

| 13. Conveying height | 15 m |

| 14. Hose length max. | 75 m |

| 15. Suitable insulation materials* | TF / EPS |

*TF: THERMOFLOC-cellulose fibre | EPS: Expanded polystyrene

THERMOBLOW 700

This machine is the most powerful machine and therefore the all-rounder among the THERMOBLOW blowing machines, as it can process all popular blown-in insulating materials, such as cellulose, wood fibre, rock wool and glass wool. Compared to the other THERMOBLOW blowing machines, the THERMOBLOW 700 uses screws rather than agitator arms to loosen up the insulating material. This machine is particularly suitable for construction projects where very large quantities of blown-in insulating materials have to be processed.

| Performance features | |

|---|---|

| 1. Power/material processing speed | 1.495 Kg |

| 2. Drive motor | 1,5 hp / 1,12 kWh |

| 3. Connected load | 2 X 230V /16 Amp. |

| 4. Blower | 2 x 1,6 kWh |

| 5. Blower control | Manuell |

| 6. Amount of material control | Material slider |

| 7. Opening rotary feeder | V = ca. 25,4 l |

| 8. Dimensions (L x W x H) | 67 x 122 x 125 cm |

| 9. Weight without accoessories | ca. 290 kg |

| 10. Hopper size | ca. 0,4 m³ |

| 11. Machine control | Funkfernsteuerung |

| 12. Conveying height | 27 m |

| 13. Hose length max. | 120 m |

| 14. Suitable insulation materials* | TF / EPS / HF / MF |

*TF: THERMOFLOC-cellulose fibre | WF: Wood fibre | MF: Mineral fibre | EPS: Expanded polystyrene

Advantages for installer and builder

Our special method of installation has considerable advantages for the installer as well as the builder. Benefits for the end-user include having an uninterrupted insulation layer that is free of thermal bridges. Existing roofs can be insulated later without removing the roof tiles and an insulation layer that is open to diffusion, and ecologically compatible with a cozy atmosphere can be created.

For many decades, the THERMOFLOC blowing technology system has been providing insulation solutions throughout the building fabric for new building projects as well as renovation or retrofitting of existing buildings.

Important application areas:

- Roof (pitched, hipped and flat)

- External and internal walls

- Top-storey ceiling

New products and application areas

- THERMOFLOC Thermobag – for the insulation of existing roof areas